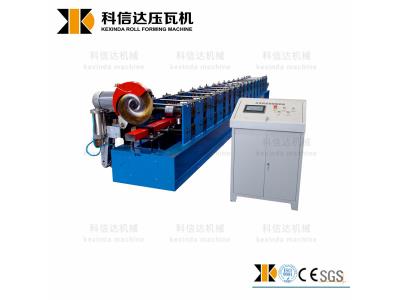

Rainwater Downpipe / Downspout Making Cold Rolling Forming Machine

Inquire NowDescription

The Rainwater Downpipe/Downspout Making Cold Rolling Forming Machine is an advanced solution for producing downspouts with precision and efficiency. This machine integrates various components, including a passive uncoiler, guiding unit, roll forming machine, cutting unit, hydraulic station, and a PLC control cabinet. It is designed to create curves for downpipes, catering to the specific requirements of engineering projects. The robust construction and user-friendly control system ensure high-quality outputs while maintaining operational stability.

Specifications

| Items | Specifications |

|---|---|

| Material Specification | Galvanized steel sheet, color sheet |

| Thickness of Coil Sheet | 0.3 – 0.8mm |

| Main Motor Power | 5.5kw |

| Forming Speed | 10-15m/min |

| Hydraulic Station Power | 3kw |

| Quantity of Stands | 18 |

| Hydraulic Pressure | 10~12Mpa |

| Control System | Panasonic PLC |

| Index Error of Length | 10m±2mm |

| Total Weight | 7T |

| Voltage | 380V 3 phase 50Hz |

Additional Information

Technical parameters of the processing line:

- Roller steps: 24 rows, three position revise

- Roller material: 45# steel, rolling chromium thickness: 0.05mm

- Diameter of active shaft: 70mm

- Wall thickness of the main forming machine: 16mm steel plate

- Main forming machine body: 350mmH steel

- Transmission chain: 25.4mm; Reducer: 4kw Xingxing Cycloid, stable operation with low noise

- Cutting method: Automatic hairless tooth saw

- Taida PLC control system: Easy operation, high precision, and stable work

- Dimensions of major structure: 10800mm x 1200mm x 900mm

- Working speed: 5-10m/min

Related Products

Product Inquiry Form

Thanks your message successfully submitted.