Description

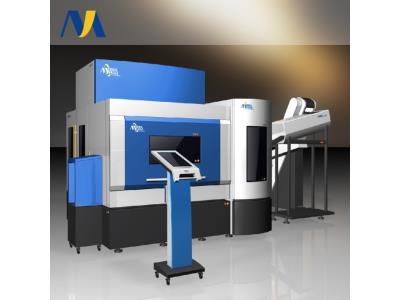

The RB Series Rotary Blow Moulding Machines represent the forefront of innovation in bottle production technology from Mega Machinery. Designed with engineered efficiency in mind, these machines require less power than previous generations, thanks to a small pitch at the pre-heater. The optimized clamping unit enhances operational flexibility, achieving impressive output rates of up to 1,800 bottles per hour per cavity for lightweight 0.5L water applications.

This advanced machinery features a unique preform feeding and loading system that prevents jams and simplifies changeover for different neck preforms. The linear oven design ensures uniform heating with reduced power consumption, while the classic double cam telescopic gripper system guarantees reliable preform and bottle transfer. Furthermore, the shell blow mould design of the mould carriers minimizes changeover times, enhancing overall productivity.

With a variety of options such as PID heating systems and patented air recovery systems, the RB Series is engineered to optimize production costs, making it an essential choice for efficient bottle manufacturing.

Specifications

| TYPE | RB4 | RB6 | RB12 | RB16 |

|---|---|---|---|---|

| Production output | ||||

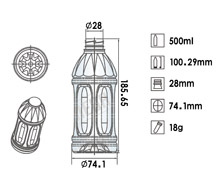

| Per cavity | 1,300 BPH | 1,400 BPH | 1,800 BPH | 1,800 BPH |

| Machine output | 5,200 BPH | 8,400 BPH | 21,600 BPH | 28,800 BPH |

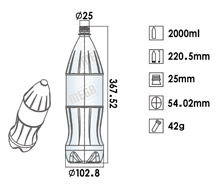

| Max. volume | 2 L | 2 L | 3 L | 3 L |

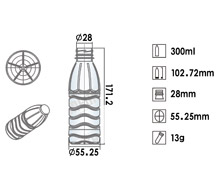

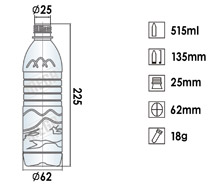

| Min. volume | 0.1 L | 0.1 L | 0.1 L | 0.1 L |

| Max. diameter | 110 mm | 110 mm | 115 mm | 115 mm |

| Max. height | 300 mm | 300 mm | 350 mm | 350 mm |

| Preform neck | Up to 42 mm | Up to 42 mm | Up to 32 mm | Up to 32 mm |

| Voltage standard | 380V/3PH/50HZ | or Special order | ||

| Power (Max load) | 90KW | 120KW | 220KW | 260KW |

| Max. blowing | 40 Bar | 40 Bar | 40 Bar | 40 Bar |

Additional Information

- Note: The Rotary blow moulding machine is also known as Rotary PET stretch blow molding machine, Rotary pet blow moulding machine, Rotary bottle blowing machine.