Description

The Ridge Cap Roll Forming Machine is an essential tool for manufacturers looking to create high-quality ridge caps for roofing systems. This advanced machine offers exceptional efficiency and precision in roll forming various materials, such as PPGI, GI, and Aluminium. Designed with user convenience in mind, the machine features a robust construction and a range of advanced components that ensure reliable performance.

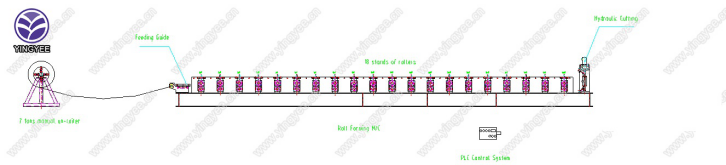

Key features include a hydraulic cutting system for clean and precise cuts, a PLC control system that enables easy operation, and adjustable input equipment for versatility in handling different materials. With a forming speed of 6 to 8 meters per minute, this machine is built to enhance productivity while maintaining the highest standards of quality in ridge cap production.

Specifications

| Feature | Details |

|---|---|

| Matching Material | PPGI/GI/Aluminium |

| Material Thickness | 0.2-0.8 mm |

| Power | 5.5 kW |

| Forming Speed | 6 – 8 m/min |

| Width of Plates | According to the drawings |

| Input Leveling Equipment | Adjustable |

| Roll Stations | 13 |

| Shaft Material & Diameter | 45# steel, Ø75 mm |

| Tolerance | ±1.5 mm |

| Drive Method | Chain driven |

| Controlling System | PLC |

| Voltage | Dependent on client specifications |

| Material of Forming Rollers | 45# steel with heat treatment and chroming |

| Side Plate | Steel plate with chroming |

| Size | Length: 7.9 m, Width: 1.45 m, Height: 1.55 m; Weight: 5.5 tons |

Additional Information

- Components:

- Manual Coiler – 1 set

- Adjustable Input Equipment – 1 set

- Main Roll Forming Machine with Chromed Plate – 1 set

- Hydraulic Cutting System – 1 set

- Hydraulic Station – 1 set

- PLC Control System – 1 set