Description

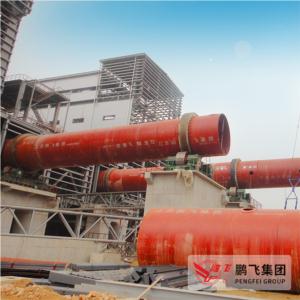

The rotary kiln is an essential industrial equipment designed for the calcination of materials. Its body is expertly constructed from rolled steel plates and features a refractory lining, ensuring durability and high-temperature resistance. The kiln operates at a slight incline, allowing for optimal material flow. Each block support device relies on three wheel belts for stability, while a gear ring encircles the inner cylinder, connected to a meshing pinion for smooth operation. The rotary kiln’s design enables efficient transmission of power from the main drive motor through a main reducer, facilitating effective rotary motion.

The working principle of the rotary kiln involves the gradual decomposition and calcination of materials as they move from the high to low end of the inclined cylinder. As fuel is injected from the kiln head, combustion gases flow through the system, enhancing heat exchange with the materials. This innovative design ensures consistent processing and high-quality output, leading to the production of clinker, which is subsequently cooled before further processing.

Composition:

- Cylinder and kiln lining

- Wheel belt

- Support device

- Drive device

- Kiln head cover

- Burner

- Smoke chamber

- Heat exchange device

- Feeding equipment

Routine Inspection:

- Drive device inspection

- Wheel belt and support device inspection

- Kiln cylinder inspection

- Sealing device inspection

Specifications

| Attribute | Details |

|---|---|

| Material | Steel Plate with Refractory Lining |

| Operating Principle | Inclined rotation for material calcination |

| Support Mechanism | Three Wheel Belts |

| Power Transmission | Main Drive Motor to Main Reducer |

Additional Information

For optimal performance, regular inspections are necessary to ensure all components are functioning effectively. Proper care and maintenance will extend the lifespan of the rotary kiln and enhance operational efficiency.