Description

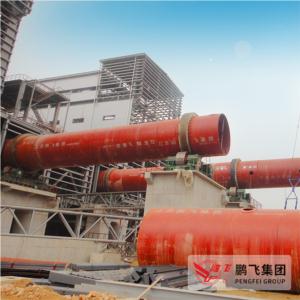

The Rotary Kiln is a state-of-the-art solution for the conversion of lithium carbonate into lithium battery production. Designed for high efficiency, this kiln processes spodumene concentrate through a series of meticulously controlled stages, ensuring optimal conversion rates. Starting from the manual transfer of spodumene concentrate, the kiln utilizes high-temperature gas to dry and crystallize the concentrate, transforming it into β-type spodumene at approximately 1200 °C. This advanced technology boasts a conversion rate of around 98%, making it a critical asset in lithium battery manufacturing.

The process includes several key stages: acidification roasting, slurry leaching, leachate purification, and evaporation and concentration of the purification liquid. Each step is engineered to minimize impurities and maximize yield, allowing for the production of high-grade lithium carbonate and anhydrous lithium chloride. The kiln’s innovative design ensures a seamless integration into existing lithium production lines, enhancing productivity and efficiency.

Specifications

| Attribute | Details |

|---|---|

| Material | Steel and refractory materials |

| Operating Temperature | Approximately 1200 °C |

| Conversion Rate | About 98% |

| Production Capacity | Battery-grade lithium carbonate |

| Process Stages | Conversion roasting, acidification roasting, slurry leaching, leachate purification, evaporation |

Additional Information

This Rotary Kiln is engineered for high efficiency, ensuring that the production of lithium carbonate meets the stringent requirements of battery-grade quality. The innovative control systems employed throughout the process enable precise adjustments to maintain optimal conditions, enhancing the overall yield and quality of the final products.