sandwich panel form rolling machine

Inquire NowDescription

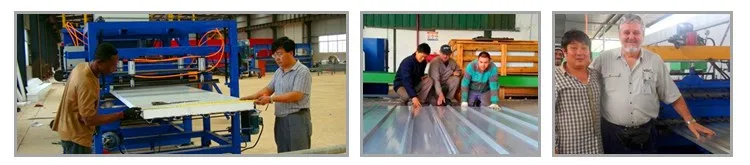

The Z-lock sandwich panel form rolling machine is an advanced iron forming machine designed specifically for producing high-quality sandwich panels used in roofing and wall applications. This state-of-the-art equipment is capable of processing various materials including EPS, rock wool, and glass silk floss, ensuring versatility and efficiency in production. With a thickness range of 0.3-0.8mm and a core thickness of 20-300mm, this machine meets diverse construction needs. Its user-friendly PLC control system enhances precision and stability during operation, making it an ideal choice for both large-scale manufacturing and custom applications.

Specifications

| Attribute | Details |

|---|---|

| Material | EPS, Rock Wool, Glass Silk Floss |

| Plate Thickness | 0.3 – 0.8 mm |

| Core Thickness | 20 – 300 mm |

| Production Capacity | 4 – 4.5 m/min (fastest), 2 – 2.5 m/min (slowest) |

| Total Power | About 30 KW |

| Weight | 25 tons |

| Dimensions | Length 35000 mm × Width 2500 mm × Height 2600 mm |

Additional Information

Processing Technique: The machine employs a composite decoiler followed by roll forming, a laminating system (including ribbon, gelatinizing, heating up, compounding, crimping, notching, and edge trimming), a cutting system, and a runout table.

Warranty: 12 months limited warranty, with parts free during warranty but shipping fees covered by the buyer.

Payment Terms: 30% down payment via T/T, with the remaining 70% due after factory inspection.

Delivery Time: 60 days after receipt of advance payment.