OEM ODM sandwich panel making machine roll forming machine for sheet metal profiles

Description

The sandwich panel making machine is a cutting-edge roll forming machine designed specifically for producing high-quality sheet metal profiles. This advanced machinery seamlessly combines the processes of rolling, laminating, and cutting to create durable sandwich panels suitable for roofing and wall applications. With the capability to handle various materials, including EPS, rock wool, and glass silk floss, this machine ensures precision and efficiency.

Featuring a user-friendly PLC control system, it offers easy operation and high precision during production. The machine’s robust build allows for a production capacity ranging from 2 to 4.5 meters per minute, depending on the glue used, making it an ideal choice for both small and large-scale manufacturing operations.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS, Rock Wool, Glass Silk Floss |

| Plate Thickness | 0.3 – 0.8 mm |

| Core Thickness | 20 – 300 mm |

| Production Capacity | 2 – 4.5 m/min |

| Total Power | Approx. 30 KW |

| Weight | 25 tons |

| Dimensions | Length 35000 mm × Width 2500 mm × Height 2600 mm |

Additional Information

Terms of Payment: 30% of the total contract value paid by T/T as down payment, with the remaining 70% to be paid after inspection in the seller’s factory.

Delivery: 60 days after receipt of advance payment.

Service: A technician will be sent to your location for machine setup, with costs for visa, roundtrip tickets, accommodation, and salary of $60/day borne by the buyer.

Warranty: 12 months limited warranty; parts are free during warranty, but the buyer pays for shipping.

Note: Custom designs are available based on your specifications, and all plate types can be adjusted to meet your needs.

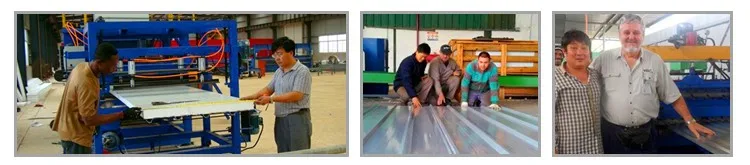

Product Pictures