OEM ODM sandwich panel making machine roll forming machine for sheet metal profiles

Description

The Xinnuo automatic EPS sandwich roof and wall panel roll forming machine is designed for efficient production of sandwich panels using various materials such as EPS, rock wool, and glass silk floss. This advanced machinery offers a comprehensive production line that includes composite decoiling, roll forming, and a high-precision cutting system. The machine is engineered for reliability and ease of operation, featuring a PLC control system that ensures consistent performance and stability.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS, Rock Wool, Glass Silk Floss |

| Plate Thickness | 0.3 – 0.8 mm |

| Core Thickness | 20 – 300 mm |

| Production Capacity | 4 – 4.5 m/min (fastest), 2 – 2.5 m/min (slowest) |

| Total Power | About 30 kW |

| Weight | 25 tons |

| Dimensions | Length 35000 mm × Width 2500 mm × Height 2600 mm |

Additional Information

Terms of Payment: 30% of the total contract value paid by T/T as a down payment, the remaining 70% to be paid by T/T after inspection by the buyer at the seller’s factory, prior to delivery.

Delivery: 60 days after receipt of advance payment.

Service: Technicians are available to fix the machine on-site, with costs covered by the buyer, including visa, roundtrip tickets, suitable accommodation, and a daily salary of $60.

Warranty: 12 months limited warranty; parts are free during the warranty period, but shipping costs are the buyer’s responsibility.

Note: The machine can be designed according to specific drawings, and all plate types can be customized based on needs.

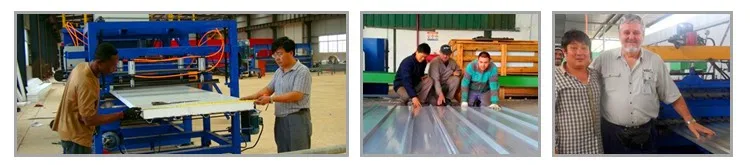

Product Pictures