sandwich panel making machine roll forming machine for sheet metal profiles

Inquire NowDescription

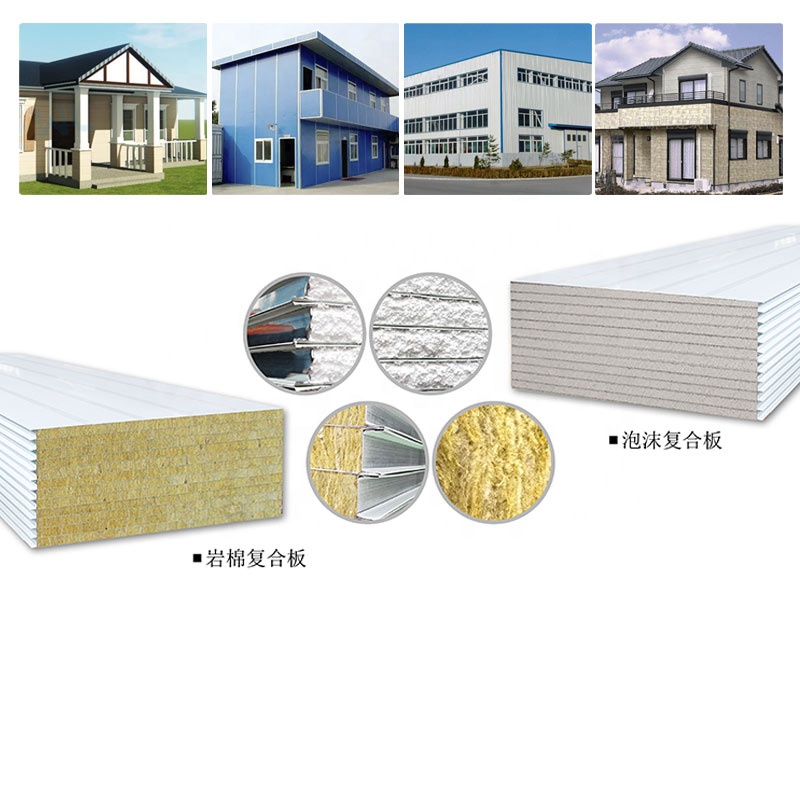

The sandwich panel making machine is a state-of-the-art roll forming machine specifically designed for the production of high-quality sandwich panels. This advanced equipment efficiently processes various materials including EPS, rock wool, and glass silk floss, making it ideal for roofing and wall applications. The machine features a PLC control system for easy operation and high precision, ensuring stable performance during production. With a production capacity ranging from 2 to 4.5 meters per minute, it optimizes workflow while maintaining quality standards.

This sandwich panels production machine line encompasses a comprehensive setup, including a composite decoiler, roll forming, laminating system, cutting system, and a runout table, streamlining the manufacturing process from start to finish.

Specifications

| Specification | Details |

|---|---|

| Coil Material | EPS, Rock Wool, Glass Silk Floss |

| Plate Thickness | 0.3 – 0.8 mm |

| Core Thickness | 20 – 300 mm |

| Production Capacity | 2 – 4.5 m/min |

| Total Power | About 30 KW |

| Weight | 25 ton |

| Dimensions | Length 35000 mm × Width 2500 mm × Height 2600 mm |

Additional Information

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller’s factory while before delivery.

Delivery: 60 days after receipt of advance payment.

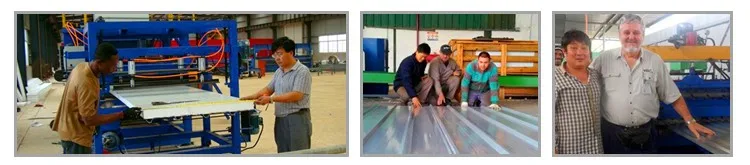

Service: Technician will be sent to your country to fix the machine. The buyer should bear all costs including visa, round-trip tickets, and suitable accommodation, also the buyer should pay a salary of $60/day.

Warranty: 12 months limited warranty. During warranty, parts are free but the buyer pays for the shipping fee.

Note: We are capable of designing machines according to your drawings, and all plate types can be changed according to your needs.

Product Pictures