sandwich panel making machine roll forming machine for sheet metal profiles

Inquire NowDescription

The sandwich panel production machine line is an advanced roll forming machine designed for the efficient manufacturing of sheet metal profiles, particularly EPS and rock wool sandwich panels. This high-performance equipment features a robust construction and is equipped with a PLC control system, ensuring ease of operation and precise outputs. The machine can handle various coil materials, including EPS, rock wool, and glass silk floss, making it versatile for different applications.

With a production capacity ranging from 2 to 4.5 m/min, this machine is optimized for both speed and quality. It is designed to produce panels with a thickness of 0.3 to 0.8 mm, and a core thickness between 20 to 300 mm. The total power requirement of approximately 30 KW and weight of 25 tons underscore its industrial capability. The dimensions of the entire production line are about 35,000 mm in length, 2,500 mm in width, and 2,600 mm in height, making it suitable for large scale manufacturing operations.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS, rock wool, glass silk floss |

| Plate Thickness | 0.3 – 0.8 mm |

| Core Thickness | 20 – 300 mm |

| Production Capacity | 2 – 4.5 m/min |

| Total Power | Approximately 30 KW |

| Weight | 25 tons |

| Dimensions | Length: 35,000 mm × Width: 2,500 mm × Height: 2,600 mm |

Additional Information

Processing Technique: The machine follows a systematic process that includes Composite Decoiler, Roll Forming, Laminating System (ribbon, gelatinizing, heating, compounding, crimping, notching, edge trimming), Cutting System, and Runout Table.

Terms of Payment: 30% of the total contract value paid by T/T as a down payment, with the remaining 70% due after inspection in the seller’s factory.

Delivery: 60 days after receipt of advance payment.

Service: Technician support is provided to fix the machine, with associated costs borne by the buyer.

Warranty: 12 months limited warranty; parts are free during the warranty period, but the buyer pays shipping.

Customization: The machine can be designed according to specific drawings, and plate types can be changed as per requirements.

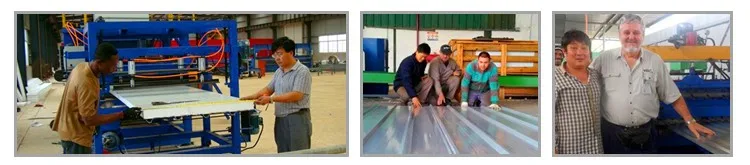

Product Pictures