Description

The Seam Lock Roll Forming Machine is a high-performance industrial machine designed for efficient metal forming. This robust machine is equipped with a comprehensive set of features for seamless operation in manufacturing. It includes a 3-ton manual de-coiler, a main roll forming machine, two electronic seam lock machines, a hydraulic cutting system, a hydraulic station, a PLC control system, and a collection table. This machine is engineered to deliver precision and quality in producing various metal profiles.

Specifications

| Component | Specifications |

|---|---|

| Manual Decoiler |

Max width of raw material: 700mm Capacity: 3000kgs Inner diameter of coil: 508±30mm |

| Roll Forming Machine |

Material: 0.5-1.0mm PPGI Minimum width size: 200mm, Maximum width size: 600mm Material input size: according to the drawing, suggest 610mm Main motor power: 7.5kw (Frequency speed control) Forming speed: 16 m/min Quantity of rollers: 16 Shaft Material and diameter: 45# forge steel Φ75mm Material Of The Stations: 18mm A3 steel Tolerance: 10m ± 1.5mm Drive method: Chain Material of forming rollers: GCr15, hard chrome coated Material of cutter blade: Cr 12 mould steel (quenched treatment 58-62℃) Voltage: 380V/3phase/50 Hz (according to customer choice) Machine weight: Around 9 tons |

| Cutting (Hydraulic Guide) |

Cutting motion: Automatic stop and cut, then restart Material of blade: GCR12 with heat treatment Length measuring: Automatic Tolerance of length: 10 ± 1.5mm Hydraulic power: 4kw, Max pressure: 10Mpa |

| PLC Control System |

Voltage: 380 V, 50 Hz, 3Phase (customizable) Automatic length and quantity measurement Control panel: Button-type switch and touch screen PLC: Delta, Touch Screen: Winview, Inverter: Schneider, Encoder: Omron |

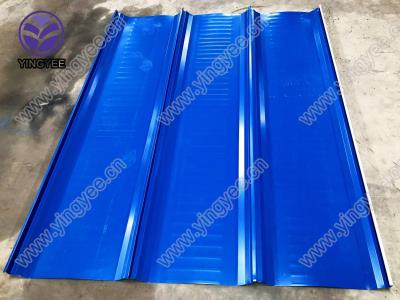

| Color | Dark Blue (or any customized color before purchase) |

| Electronic Seam Lock Machine | Includes 2 sets of good quality seam lock machines |

| Manual Seamer | 2 sets |

Additional Information

For optimal performance, ensure regular maintenance of the machine and adhere to the operational guidelines. This machine is designed for durability and efficiency in producing high-quality metal profiles.