Description

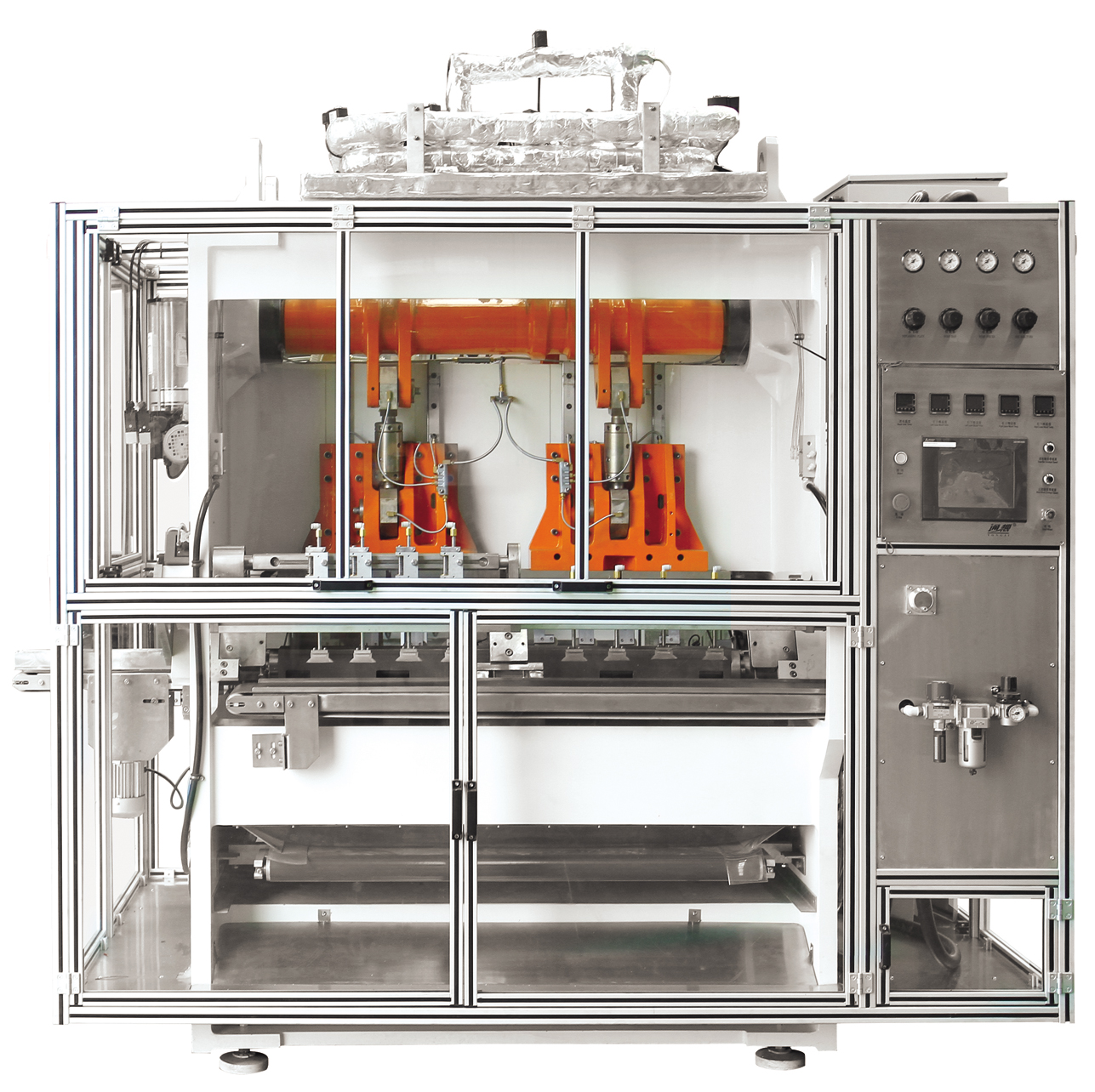

The SOAP STAMPING MACHINE is engineered for efficiency and precision in soap production. Featuring a vertical stamping design, this machine harnesses advanced technology driven by a servo control and cam system, ensuring high mechanical repeating accuracy. The innovative suction cup mechanism effortlessly picks up soap billets, places them into molds, and subsequently extracts finished soap bars onto a discharge conveyor. This fully automatic cycle is characterized by high speed, minimal vibration, and robust performance. The control system is equipped with a Schneider PLC and servo, along with a user-friendly HMI that supports both English and Chinese operating screens. For added convenience, an electrical hand wheel allows for fine adjustments and easy mold replacements. Constructed with a durable aluminum frame, the machine also incorporates safety door switches to prioritize operator safety.

Specifications

| Feature | Details |

|---|---|

| Type | Vertical Stamping Machine |

| Control System | Schneider PLC and Servo |

| Operating Screens | English/Chinese |

| Frame Material | Aluminum |

| Safety Features | Safety door switches |

| Operation | Fully automatic, high speed |

| Vibration | Low vibration |

Additional Information

For optimal performance and safety, ensure regular maintenance of the machine and adhere to operational guidelines. The machine’s design allows for easy access during mold replacements and adjustments, making it user-friendly for operators.