Description

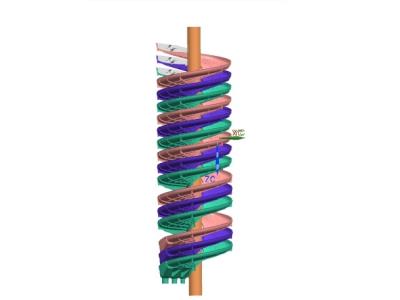

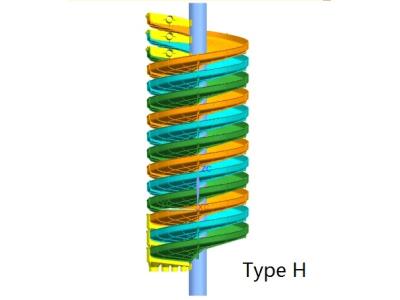

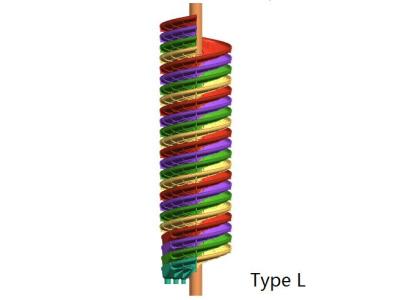

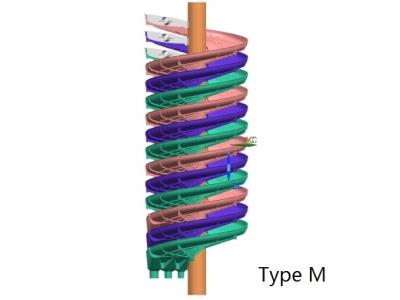

The spiral concentrator Type M+L is a cutting-edge gravity separation device designed to provide exceptional performance in various mineral processing applications. As the world leader in spiral technology, this concentrator offers unparalleled confidence in the efficiency of gravity separation circuits. Manufactured in Australia, it features a robust construction capable of producing over 20,000 starts annually, ensuring reliability and durability. The M+L model is engineered for optimal separation with a range of features that enhance recovery and concentrate quality.

Key features include a replaceable modular cast polyurethane feed box for extended service life, a tailored splitter configuration for specific applications, and a concentrate diverter that maximizes product grade. Additionally, re-pulping devices are integrated to further enhance recovery, while the cast polyurethane product collector box prevents splash collection. The design also incorporates an engaged launder system and accurate feed distribution for improved recovery rates, all contributing to a simplified process circuit that reduces capital costs.

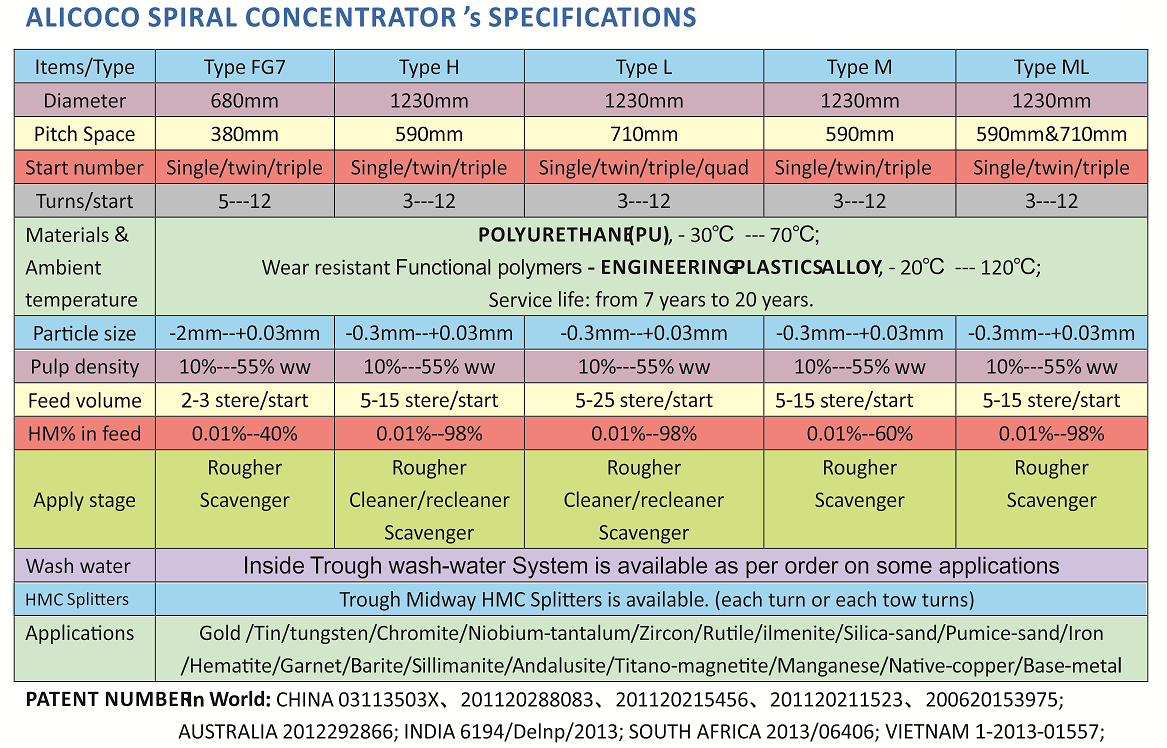

Specifications

| Feature | Details |

|---|---|

| Material | Cast Polyurethane |

| Configurations | Single, Twin, Triple, Quad Troughs |

| Spiral Banks | Up to 48 Starts |

| Applications | Mineral Concentration (Rutile, Ilmenite, Zircon, etc.) |

| Operating Life | Long Operating Life |

Additional Information

The spiral concentrator Type M+L is suitable for a variety of applications, including the concentration of rutile, ilmenite, zircon, iron ore, and gold recovery. Its low capital cost and minimal maintenance requirements make it an economical choice for mineral processing. With consistent separation efficiency and comprehensive process engineering support, this concentrator is designed to meet the demands of modern mining operations.