Description

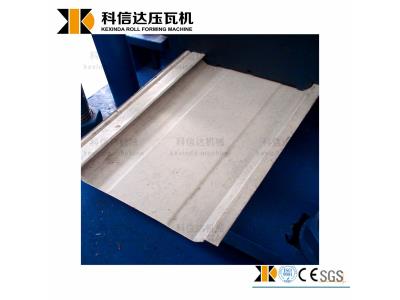

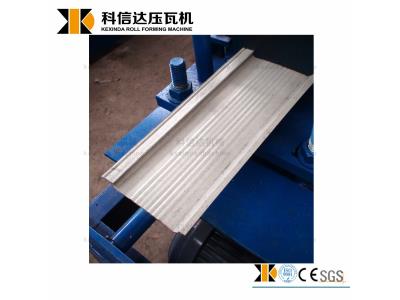

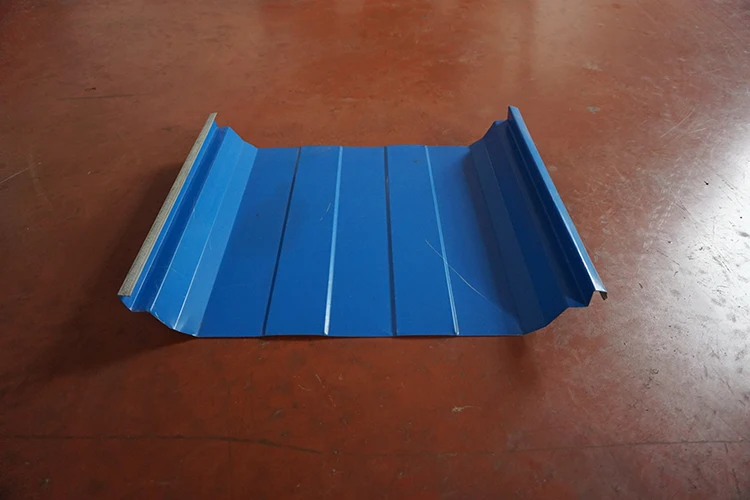

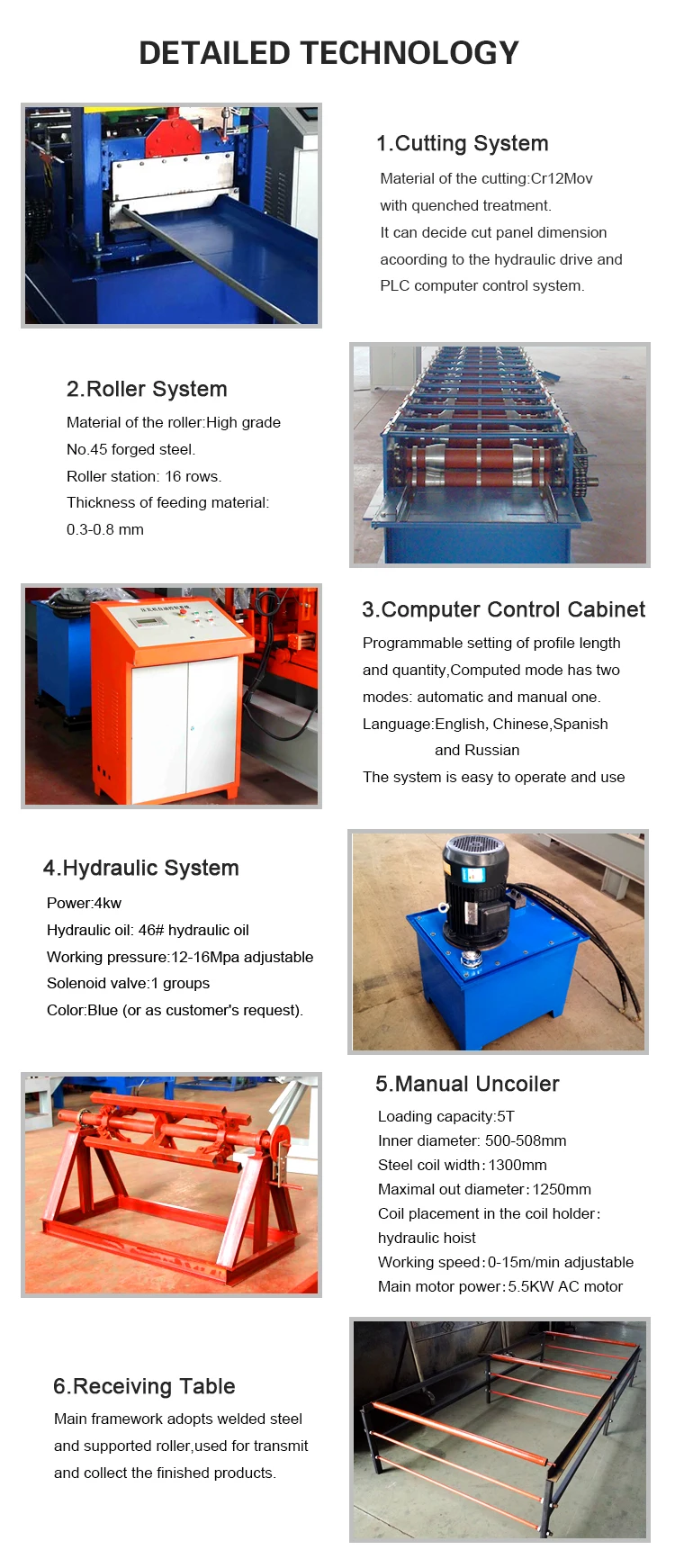

The Standing Seam Metal Roof Panel Machine is a cutting-edge self-locking roof sheet roll forming machine designed for producing high-quality metal roof panels. This robust machine is suitable for processing various materials, including color steel plates, galvanized sheets, and aluminum coils. Engineered for efficiency and reliability, it features an advanced roller station that can accommodate up to 16 rows, allowing for custom configurations to meet diverse production needs. Its precise engineering ensures that each panel is formed to exact specifications, making it an essential tool for roofing contractors and manufacturers alike.

Specifications

| No. | Main Parameter | Details |

|---|---|---|

| 1 | Suitable to Process | Color steel plate, galvanized sheet, aluminum coils, etc. |

| 2 | Width of the Feeding Material | 820/470/760 mm |

| 3 | Roller Station | 16 rows or custom |

| 4 | Thickness of Feeding Material | 0.16-0.3 mm |

| 5 | Power | 5.5 kW |

| 7 | Productivity | 6-12 m/min |

| 8 | Diameter of the Roller | Φ70 mm |

| 9 | Weight | About 4 T |

| 10 | Size | 8200 x 950 x 1000 mm |

| 11 | Voltage | 380V 50Hz 3 phases |

| 12 | Rolling Material | Carbon Steel 45# |

| 13 | Material of the Cutting Plate | Cr12 |

Additional Information

For optimal performance, ensure regular maintenance of the machine and adhere to the recommended operational guidelines. The machine requires a 30% down payment, with the remaining 70% due upon delivery.