Standing seam profile roll forming machine

Inquire NowDescription

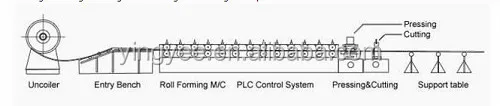

The Standing Seam Profile Roll Forming Machine is an innovative solution designed for the efficient production of standing seam roofing and wall panels. This state-of-the-art equipment simplifies the process of forming metal panels by incorporating various stages seamlessly, ensuring precision and speed. The machine’s working flow includes decoiling, feeding, guiding, roll forming, cutting to length, and finally, an output table for finished products. Crafted to handle materials like galvanized steel or PPGI, it is versatile and adaptable to different production needs.

Specifications

| Attribute | Details |

|---|---|

| Matching Material | Galvanized or PPGI |

| Material Thickness Range | 0.2 – 1 mm |

| Forming Speed | 10 – 15 M/MIN |

| Power | 4 KW |

| Quantity of Rollers | 14 rows |

| Shaft Material and Diameter | 70 mm, material is 40CR |

| Body Material | 400H steel, Wall Panel: 20 mm Q195 steel (all with electrostatic spraying) |

| Tolerance | ± 1.5 mm |

| Controlling System | PLC |

| Total Weight | About 3 Tons |

| Voltage | 380V / 3 phase / 50 Hz |

| Size of the Machine | L*W*H: 7 m * 1.5 m * 1.5 m |

| Material of Forming Rollers | Gcr 15, coated with chromed treatment, HRC 58-62 |

| Material of Cutter Blade | Cr 12 mould steel with quenched treatment, HRC 58-62 |

| Temperature | 60°C |

Additional Information

- Designed for high efficiency and precision in metal panel production.

- Suitable for various applications including roofing, wall cladding, and more.

Related Products

Product Inquiry Form

Thanks your message successfully submitted.