Description

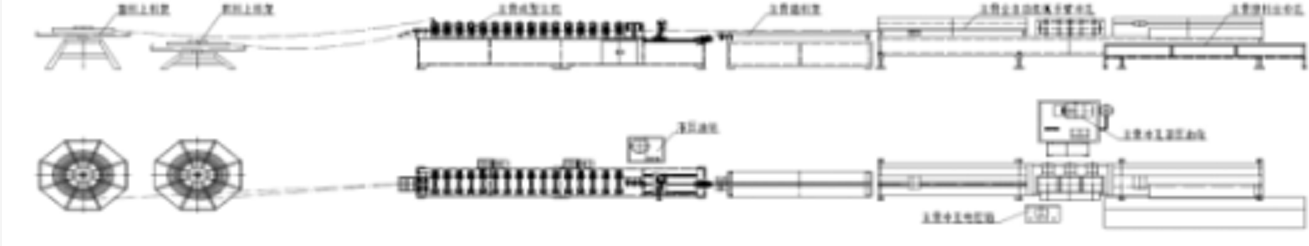

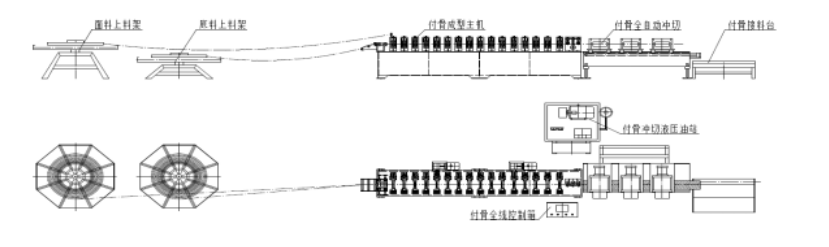

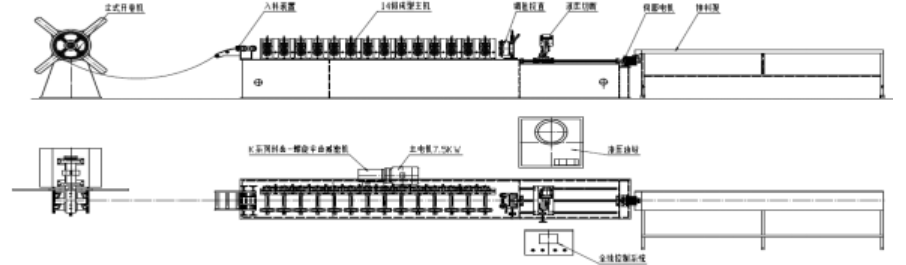

Introducing the Automatic T Ceiling Production Line, a state-of-the-art solution designed for high precision manufacturing of ceiling components. This production line encompasses three main functions: the Main Tee Production Line, Cross Tee Production Line, and Angle Production Line. Each segment is engineered to ensure flawless production processes, resulting in exceptionally crafted final products that meet industry standards.

The Automatic T Ceiling Production Line is suitable for various applications, providing versatility in construction projects. Its advanced technical processes and robust machine parameters guarantee efficiency and high-quality output, making it an essential investment for manufacturers seeking to enhance their production capabilities.

Specifications

| Feature | Details |

|---|---|

| Main Tee Production Line |

|

| Cross Tee Production Line |

|

| Angle Production Line |

|

Additional Information

For optimal performance, ensure that the machinery is regularly maintained and operated by trained personnel. This production line is designed to deliver consistent quality and efficiency in manufacturing, making it a valuable addition to any production facility.