Description

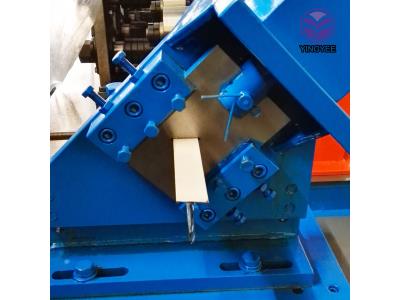

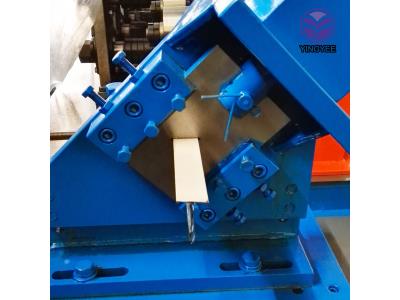

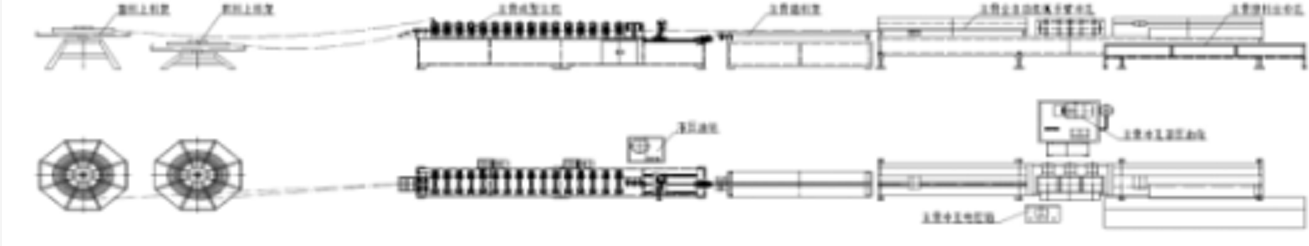

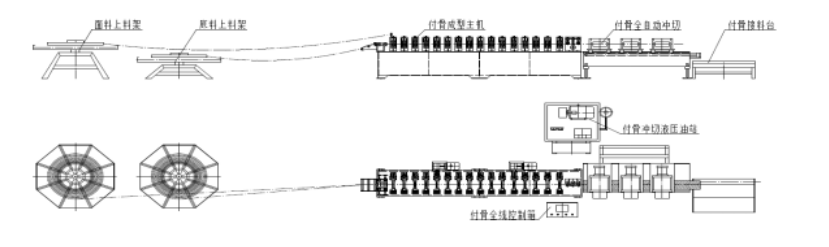

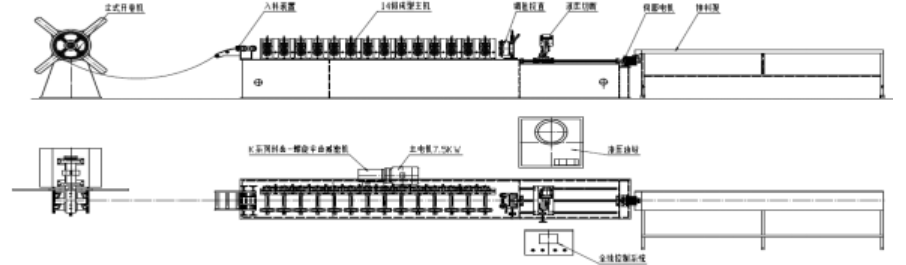

The T-Ceiling production line is a highly efficient automated system designed to streamline the manufacturing of ceiling components, including main tees, cross tees, and angles. This innovative production line features advanced technology to facilitate the forming and assembly of ceiling grid elements, ensuring precision and quality in every piece produced.

Main Features:

- Automatic operation for increased productivity.

- Designed for manufacturing main tees, cross tees, and angles.

- Utilizes high-quality materials for durability and reliability.

Specifications

| Component | Specifications |

|---|---|

| Main Tee Roll Forming Machine |

|

| Cross Tee Roll Forming Machine |

|

| Angle Roll Forming Machine |

|

Additional Information

This production line is designed to enhance efficiency and output in manufacturing operations. Regular maintenance is recommended to ensure optimal performance and longevity of the machinery.