Description

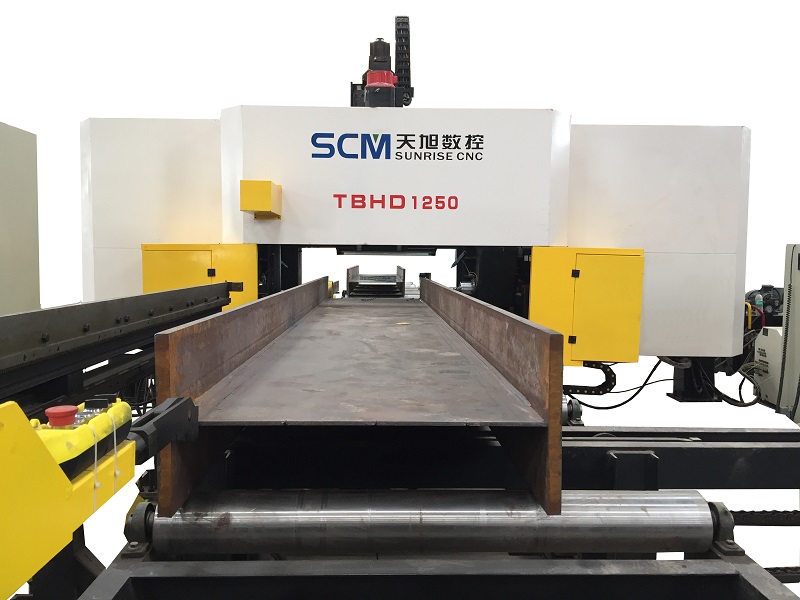

This high-speed CNC Beam Drilling Machine, model TBHD1250, is engineered for precision and efficiency, making it essential for industries such as construction and bridge building. Designed to process holes in H-beams and channel beams swiftly, it features a CNC-controlled system driven by servo motors for exceptional positioning and feeding accuracy. The machine boasts a robust casting body and drilling units that enhance stability during high-speed operations. With a precision spindle sourced from a renowned Taiwanese brand, it accommodates both hard alloy and high-speed steel drills, ensuring versatility in various applications.

The TBHD1250 is equipped with advanced features, including a trolley conveyor system for accurate positioning and an inline tool magazine that facilitates automatic tool changes for multiple hole diameters. Its FAGOR CNC control system is designed to withstand interference, delivering high precision through digital communication. Key components are sourced from internationally acclaimed brands, ensuring reliability and stability in its hydraulic and electrical systems.

Specifications

| Attribute | Description |

|---|---|

| Model | TBHD1250 |

| Work piece size | H beam – Web (mm): 150~1250, Flange (mm): 75~600 |

| Max. material length (mm) | 12000/15000 (optional) |

| Spindle Quantity | 3 |

| Spindle rotation speed (r/min) | 200~3000 |

| Feeding speed (mm/min) | 0~5000 |

| Max. hole diameter (mm) | Cemented carbide: φ30, Twist drill: φ40 |

| Control system | CNC system: FAGOR 8070 |

| Overall dimension (L×W×H) (mm) | About 6000×2100×3500 |

| Main Machine weight (Kg) | About 8500 |

Additional Information

– The CNC axes quantity is 7+3, providing enhanced operational flexibility.

– The machine supports a working power of three-phase four-wire system at 380±10%V, 50HZ.

– It operates effectively within a temperature range of 0℃ to 40℃ and a humidity level of ≤75%.