Description

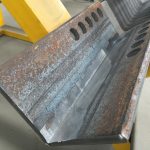

The TGQ Angle Root Milling Machine is an advanced industrial tool designed for high-speed milling with exceptional efficiency and precision. Featuring special cutters with multiple blades, this machine ensures a smooth surface finish while completing the molding process in one go. It offers flexibility in operation, allowing for both single-stage and continuous cutting based on user requirements. The TGQ machine simplifies the milling process, reducing the operational demands on workers with its high degree of automation. Capable of processing angles up to L180 × 180 × 18 and lengths of up to 800mm in just 2-3 minutes, one operator can efficiently manage two machines simultaneously. Compared to traditional planers, this milling machine circumvents limitations such as length restrictions and complex setups, making it not only convenient but also significantly enhances production efficiency. With features like adjustable operation, stable performance, and air pressure safety mechanisms, the TGQ Angle Root Milling Machine is a versatile solution for various milling needs.

Specifications

| Attribute | TGQ200 | TGQ250 |

|---|---|---|

| Model | TGQ200 | TGQ250 |

| Total power | 10KW | 7KW |

| Single-spindle power | 4KW | 3KW |

| Power supply | 380V, 50Hz | 380V, 50Hz |

| Air supply | 0.6MPa~0.7MPa | 0.6MPa~0.8MPa |

| Cutting Speed | 150~400rpm | 0~400rpm |

| Diameter of cutting plate | 100mm | 120mm |

| Feeding speed | 230~500mm/min | 0~500mm/min |

| Rotation of spindle | 450rpm | 400rpm |

| Quantity axis | 2 | 2 |

| Quantity feeding motor | 2 | 2 |

| Quantity pressure cylinder | 4 | 4 |

| Angle processing size | L63~L200 | L63~L200 |

| Length of angle | 300mm~+∞ (Processing length unlimited) | 350mm~+∞ (Processing length unlimited) |

| Mode pressure | Have the function workpiece automatic positioning | |

| Overall dimensions | 2250×1290×1900mm | 2250×1290×1900mm |

Additional Information

- Operation is simple, with flexible adjustments for different settings.

- High automation enables continuous and intermittent feeding, enhancing productivity.

- Equipped with air pressure protection to prevent safety incidents from low pressure.