Description

The TPPD103 CNC Hydraulic Plate Punching, Marking & Drilling Machine is an advanced piece of equipment designed for precision work in industries such as iron tower construction, steel structures, and bridge fabrication. This machine excels in punching, marking, and drilling various metal plates, making it an invaluable asset for professionals in the metalworking field.

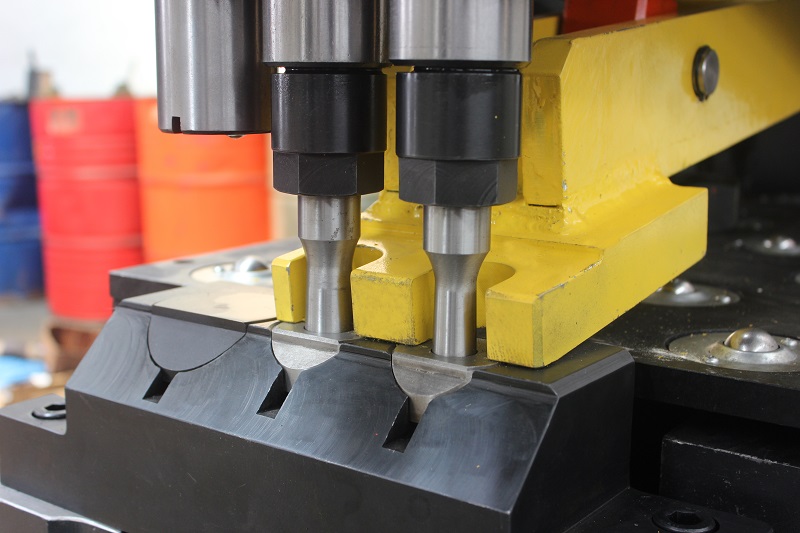

Constructed with a robust C-type plate welding frame, the TPPD103 offers impressive rigidity and ample handling space. It features three automatic die-stations, including one specifically for marking, ensuring versatility and efficiency. The clamping system is adaptable for different workpieces, with a zero baffle as a datum mark and a rolling-ball working table for optimal support.

Equipped with a state-of-the-art CNC technology, the machine’s servo motor controls X & Y axis movements, guaranteeing high precision throughout the machining process. Users can easily input workpiece dimensions into the computer, allowing for repeat programming and streamlined operations. The machine also boasts quick programming capabilities, accommodating input from CAD/CAM systems, and offers a self-diagnosis feature for troubleshooting.

Specifications

| Specification | Details |

|---|---|

| Model | TPPD103 |

| Max size of work piece L×W (mm) | 1500×800 |

| Max. diameter of punching (mm) | Φ26 |

| Plate thickness of punching (mm) | 5~25 (Q235) 5~20 (Q345) |

| Max. diameter of drilling (mm) | Φ50 |

| Plate thickness of drilling (mm) | 40 |

| Punching force (kN) | 1000 |

| Marking force (kN) | 800 |

| Min. distance between hole and plate edge (mm) | Punching: 25 Drilling: Depends on hole diameter |

| Dimensions of characters (mm) | 14×10×19 |

| Quantity of characters | 12 |

| Die-stations | 3 |

| Feeding speed of drilling (mm/min) | 25~280 |

| Stroke of drilling spindle (mm) | 180 |

| Rotation speed of drilling spindle (r/min) | 120~560 |

| Programming mode | Auto CAD or lofting software |

| Overall dimensions L×W×H (mm) | 3200×3000×2600 |

| Weight of machine (kg) | Approx. 5800 |

Additional Information

- Lightens the workload for operators, reducing physical strain.

- Modular assembly of key components simplifies maintenance and repairs.

- Integrates advanced hydraulic systems for efficient operation.