Description

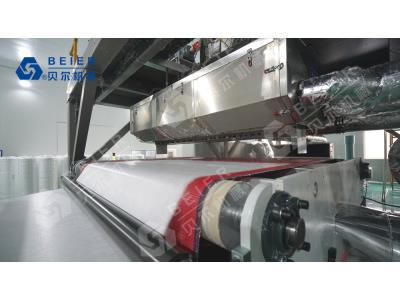

The TSK Parallel Twin Screw Water-ring/Strand/Die-face Hot Cutting Pelletizing line is engineered for superior performance and reliability in polymer processing. Featuring a modular design, this advanced twin screw extruder allows for extensive customization to meet diverse processing needs. The system is equipped with various barrel types, including feeding, side feeding, and vacuum vent barrels, and utilizes high-quality materials such as nitride and bimetallic steel to ensure durability. Its innovative block structure optimizes the sequence of processing stages—conveying, plasticization, compounding, homogenization, degassing, and pressure building—making it exceptionally efficient.

With multiple cutting systems available, including strands pelletizing, hot-face cutting, and underwater pelletizing, the TSK extruder adapts to various production requirements. The control system, which can be instrument-controlled or PLC-controlled, incorporates European brand components for enhanced reliability and performance.

Specifications

| Model | Screw Dia. (mm) | L/D | Motor Power (kW) | Capacity (kg/h) | Max Screw Speed (rpm) |

|---|---|---|---|---|---|

| TSK-35 | 35.6 | 32-52 | 22 | 50-80 | 600 |

| TSK-50 | 50.5 | 32-52 | 55 | 120-180 | 600 |

| TSK-65 | 62.4 | 32-52 | 90-110 | 240-350 | 600 |

| TSK-75 | 71.2 | 32-52 | 132-160 | 400-550 | 600 |

| TSK-95 | 91 | 32-48 | 280-315 | 800-1100 | 500 |

Additional Information

Advantages of filler master batch:

- Reduce costs

- Reduce product shrinkage

- Increase the hardness of the product

Production line advantages:

- Produces high-quality, high-quantity filler master batch

- Operates with high efficiency

- Features computerized high automation

Pelletizing Methods:

- Water-ring Pelletizing

- Cold-strand Pelletizing

- Die-face Hot-air Pelletizing

Applications:

- Master batch: PE, ABS, PS, EVA

- Filling and modifying: PE, P EVA + CaCO3, etc.

- Blending and modifying: PC + ABS, PA + ABS, etc.

- Glass fiber reinforcement: PP/PA + Glass Fibers

- Cable materials