Description

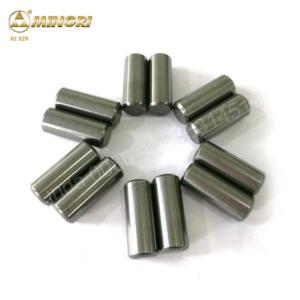

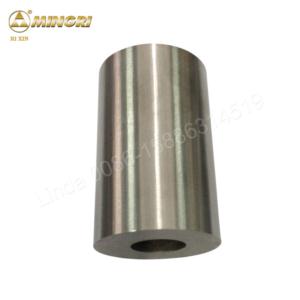

Tungsten Carbide Stud for HPGR

Tungsten carbide studs are specifically designed for use on the rollers of High Pressure Grinding Rolls (HPGR). These studs are renowned for their exceptional hardness, strength, and impact resistance, which significantly enhance the service life and operational efficiency of HPGR machines. In fact, tungsten carbide studs can last up to 10 times longer than traditional hardfacing rollers, making them a superior choice for heavy-duty applications.

Our Advantages:

- High Production Capacity and Advanced Technologies: Zhuzhou Mingri employs mature technologies in tungsten carbide stud production, utilizing a 60T TPA pressing machine to ensure high-quality green compacts and a HIP sintering furnace capable of sintering up to 1000 kilograms of studs at a time.

- Expert Team with Strong R&D Capability: Our dedicated engineers are focused on tracking the application of our products and innovating new materials with enhanced properties. We prioritize constant communication with our customers, offering enthusiastic and considerate service.

- Customized Solutions: Our independent mold designing team and production workshop enable us to deliver customized products efficiently and with lasting quality.

- Proven Track Record: Over the past 6 years, we have successfully supplied a total of 800 tons of tungsten carbide studs to various companies, earning a solid reputation in the industry.

Specifications

| Property | Details |

|---|---|

| Material | Tungsten Carbide |

| Service Life | Up to 10 times longer than traditional hardfacing rollers |

| Production Capacity | 60T TPA pressing machine |

| Sintering Capacity | 1000 kilograms per batch |

| Total Supplied | 800 tons |

Additional Information

- Constant communication with customers for feedback and support.

- Customized solutions available for specific applications.

- Strong reputation built over 6 years in the industry.