Description

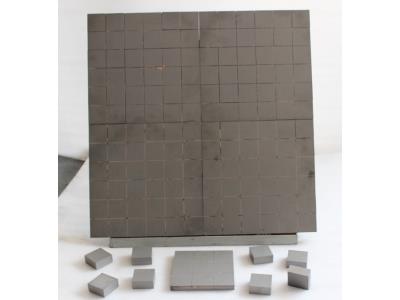

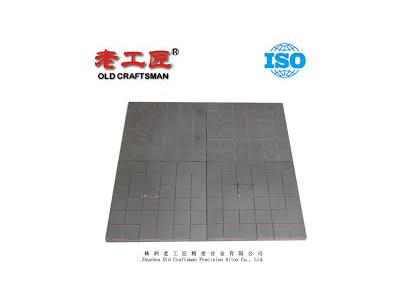

Introducing the Tungsten Cemented Carbide Welding Plate, expertly designed for use in mining tools. This product is crafted from 100% raw tungsten carbide material, ensuring exceptional quality and durability. Utilizing a high-pressure sintering process, it boasts remarkable hardness and wear resistance, making it an ideal choice for heavy-duty applications.

Available in various sizes and types, each plate is reasonably priced and delivered quickly. We offer OEM customization options, accommodating small orders and providing professional technical support. With ISO 9001 Certification, our commitment to quality is guaranteed. For further details on specific types, please reach out to us.

Specifications

| Dimension (mm) | Tolerance | |||

|---|---|---|---|---|

| Unground | Ground | |||

| Height | Length | Width | ||

| 100 X 100 (1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 105 X 105 (1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 120 X 120 (1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 150 X 150 (10.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 200 X 200 (10.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 200 X 100 (1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 200 X 160 (1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 150 X 120 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 150 X 100 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 100 X 90 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 100 X 80 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 100 X 50 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 100 X 60 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 120 X 50 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| 120 X 80 (1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

| Notes: We supply the carbide Plates according to the customers’ requirements. | ||||

Additional Information

The welding plates can be manufactured in lengths ranging from 10.0 to 500 mm and widths from 10.0 to 500 mm, with a height of 1.0 to 100.0 mm. The surface options include sintered and ground surfaces, and the composition can vary (e.g., WC+Co, WC+TiC+TaC+Co). Furthermore, we can design products according to the customer’s requirements.

Grade Information

| GRADE | ISO CODE | COBALT CONTENT (%) | DENSITY (g/cm3) | HARDNESS (HRA) |

|---|---|---|---|---|

| K10T | K05-K10 | 4.5-6.0 | 14.95-15.05 | 92.7 |

| YG8 | K30 | 8 | 14.8 | 89.5 |

| YG6 | K20 | 6 | 14.95 | 90.5 |

| YG6X | K10 | 6 | 14.95 | 91.5 |

| YL10.2 | K30 | 10 | 14.5 | 91.8 |

| YG13X | K30-K40 | 13 | 14.3 | 89.5 |

| YG15 | K40 | 15 | 14 | 87.5 |

Applications

Tungsten carbide specialized tile plates are essential for mineral processing and transportation in mechanical or conveyor systems. Common applications include fixed plant equipment such as chutes, feed bins, fan boxes, crushers, screen plates, fan blades, cyclones, and pipe spools. The small carbide plate pieces are highly sought after across various industries, especially mining, due to their extended lifespan and ease of replacement.