Description

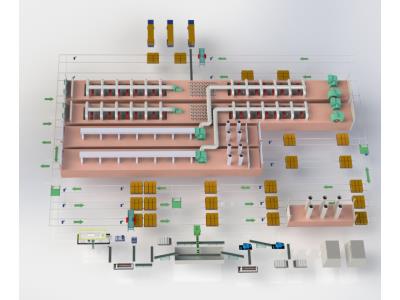

The Turnkey Project for an Automated Clay Bricks Manufacturing Plant is an all-inclusive solution designed to streamline the production of high-quality clay bricks. This comprehensive package encompasses everything from initial design and civil construction to the installation of machinery, debugging, trial running, and after-sale service, ensuring a hassle-free setup experience. The plant features an innovative firing thermal energy system that utilizes coal, which is mixed during the preparation phase to provide up to 80% of the required energy efficiently and cleanly. Final fuelling is managed automatically, allowing for precise control of the firing curve.

Combustion air is carefully pre-heated in the cooling zone, optimizing energy use. The system also incorporates advanced features such as a one-time palletizing burning system, a tunnel dryer, and a tunnel kiln. This state-of-the-art setup uses pulverized coal with an outer automatic feeding system for external combustion, while recycling heat from the kiln cooling zone to efficiently power the dryer, making it a highly sustainable option for brick production.

Specifications

| Feature | Description |

|---|---|

| System Type | Full Automation for Green Bricks Production |

| Firing Energy Source | Coal with Automatic Feeding System |

| Cooling System | Pre-heating of Combustion Air |

| Heat Recycling | From Kiln Cooling Zone to Dryer |

| Palletizing System | One Time Palletizing Burning System |

| Drying Method | Tunnel Dryer |

| Firing Method | Tunnel Kiln |