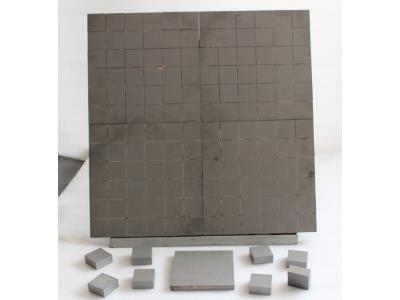

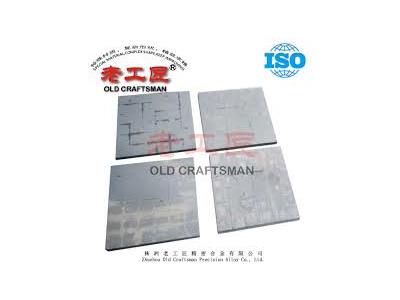

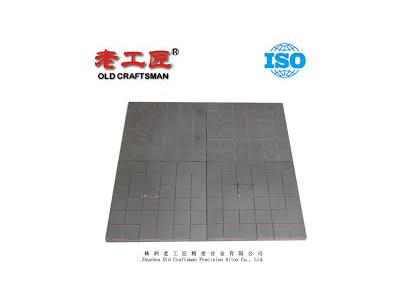

OEM ODM Various Size Vacuum Welding Plate Tungsten Cemented Carbide

Description

Introducing the innovative Vacuum Welding Tungsten Cemented Carbide Plates, meticulously designed for superior performance in various industrial applications. Crafted from 100% raw tungsten carbide material, these plates undergo a high-pressure sintering process, resulting in exceptional hardness and wear resistance. Available in various sizes and configurations, our plates offer flexibility to meet diverse project needs, all at a reasonable price point with fast delivery times.

Our advanced vacuum welding technology ensures a seamless bond between carbide and steel, overcoming the challenges of traditional adhesive methods. This new approach significantly reduces the risk of separation during use and enhances the overall quality of the final product. Designed for longevity, each mold can withstand up to 50,000 uses, minimizing downtime and maintenance costs.

These tungsten carbide plates are not only engineered for durability but also cater to the stringent requirements of modern manufacturing processes, making them an essential component in various industries, including mining and mineral processing. Experience the perfect blend of strength, heat resistance, and wear resistance with our Vacuum Welding Tungsten Cemented Carbide Plates.

Specifications

| Feature | Details |

|---|---|

| Material | Tungsten Cemented Carbide |

| Production Process | Vacuum Welding |

| Hardness | High |

| Wear Resistance | Excellent |

| Certification | ISO 9001 |

| Usage Life | Up to 50,000 uses |

| Order Type | OEM Customized (Small Orders Accepted) |

Additional Information

- Typical Applications: Mineral processing, conveyor systems, crushers, screen plates, and more.

- Benefits: Reduced production costs, enhanced durability, and easier replacement.

- Professional technical support available for all inquiries.