Description

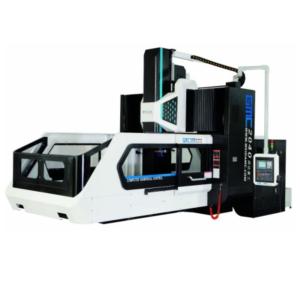

Introducing the Vertical Machining Center, a sophisticated solution tailored for precision machining tasks. This machine stands out with its high-performance capabilities, featuring a robust Taiwan spindle operating at BT40-8000RPM, designed to handle diverse machining tasks with utmost efficiency. Its advanced linear guide system incorporates Taiwan Hiwin technology, ensuring exceptional stability and accuracy across the X, Y, and Z axes. The Vertical Machining Center is equipped with a 24-piece arm type tool magazine that facilitates quick tool changes, optimizing your workflow.

Designed for durability and ease of use, the center includes an auto centralized lubrication system and a spindle blowing chip removal system. Additionally, it features both water and air cooling mechanisms to enhance performance during extended operation. Safety is paramount, with essential features such as a safety door lock and alarm light to ensure operator protection. This machine is perfect for both small workshops and large manufacturing setups, delivering precise machining and reliable performance.

Specifications

| Specification | Unit | Value |

|---|---|---|

| Model | – | VMC850 |

| Table size | mm | 1000×500 |

| T slot | No. | 5 |

| Centre distance | mm | 90 |

| T-Width | mm | 18 |

| Max. load of worktable | kg | 500 |

| Longitudinal travel | mm | 800 |

| Cross travel | mm | 500 |

| Vertical travel | mm | 550 |

| Spindle nose to table surface | mm | 150-700 |

| Spindle taper | – | BT40 |

| Speed Range | rpm | 40-6000 |

| Spindle output torque (Max.) | N.M | 70/95 |

| Spindle motor power | kw | 11/15 |

| Cuttin feed X/Y/Z | mm / min | 1-10000 |

| Rapid feed X/Y/Z | m / min | 30/30/24 |

| X/Y/Z lead screw size | mm | 40×16 |

| Tool magazine capacity | piece | 24 |

| Tool magazine type | – | arm type |

| Max. tool weight | kg | 8 |

| Max. Tool dia. (full/empty) | – | 78/120 |

| Max. Tool length | mm | 300 |

| Tool changing time (tool to tool/cut to cut) | s | 1.55/5 |

| Positioning accuracy | mm | ±0.005/300 JIS |

| Repeat positioning accuracy | mm | ±0.005/300 JIS |

Additional Information

- Auto centralized lubrication system for ease of maintenance.

- Spindle blowing chip removal system ensures a clean working environment.

- Electrical handwheel, working lamp, and an alarm light for enhanced usability and safety.

- Water cooling and air cooling systems for improved thermal management during operations.