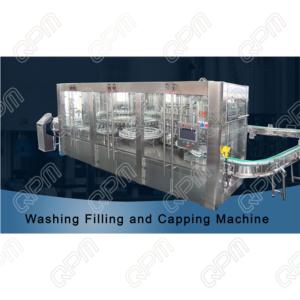

Description

The Washing-Filling-Capping Monobloc Machine is an advanced solution designed specifically for the seamless bottling of wine. This all-in-one unit simplifies the bottling process by integrating essential functions such as rinsing, nitrogen injecting, filling, and corking. Engineered for efficiency, the machine initiates operations the moment a bottle is detected and halts automatically when no bottles are present or if a bottle becomes stuck.

Equipped with an overload clutch protection device, it ensures that if any obstruction occurs, the machine will shut down to prevent damage to both the bottles and the equipment. The robust design features integrated safety guards made of stainless steel Aisi 304, adhering to the strict “CE” norms, and allows for easy inspection by removing the safety panels. Additionally, the chassis frame is constructed with fully electro-welded tubular rods in AISI 304 stainless steel, ensuring durability and resistance to corrosion. In the event of an emergency stop, the conveyor halts simultaneously, providing an extra layer of safety for operators.

Specifications

| Feature | Details |

|---|---|

| Functionality | Washing, Rinsing, Nitrogen Injecting, Filling, Corking |

| Material | Stainless Steel Aisi 304 |

| Safety Compliance | CE Norms |

| Frame Construction | Electro-welded Tubular Rods |

| Emergency Features | Overload Clutch Protection, Simultaneous Conveyor Stop |

Additional Information

- Machine starts when a bottle is detected; stops when no bottle is present or if a bottle is stuck.

- Integrated safety features for operator protection.