Description

The WATER INVERTER is an advanced device designed to enhance the performance of traditional electric pumps, including surface, vertical, and submersible types. It intelligently controls the start and stop functions while modulating motor rotations based on the system’s water demand, ensuring a seamless operation. The inverter significantly reduces hammering effects and avoids inrush starting currents, providing constant pressure throughout the system.

Equipped with an integrated pressure transducer, the WATER INVERTER offers various protective features, such as dry running protection, automatic reset during dry conditions, and safeguards against leakages, overpressure, overheating, rotor blocking, and abnormal power supply. The device also includes motor overcurrent control and a digital display that indicates pressure, voltage, current, and motor frequency, allowing for easy monitoring and adjustments.

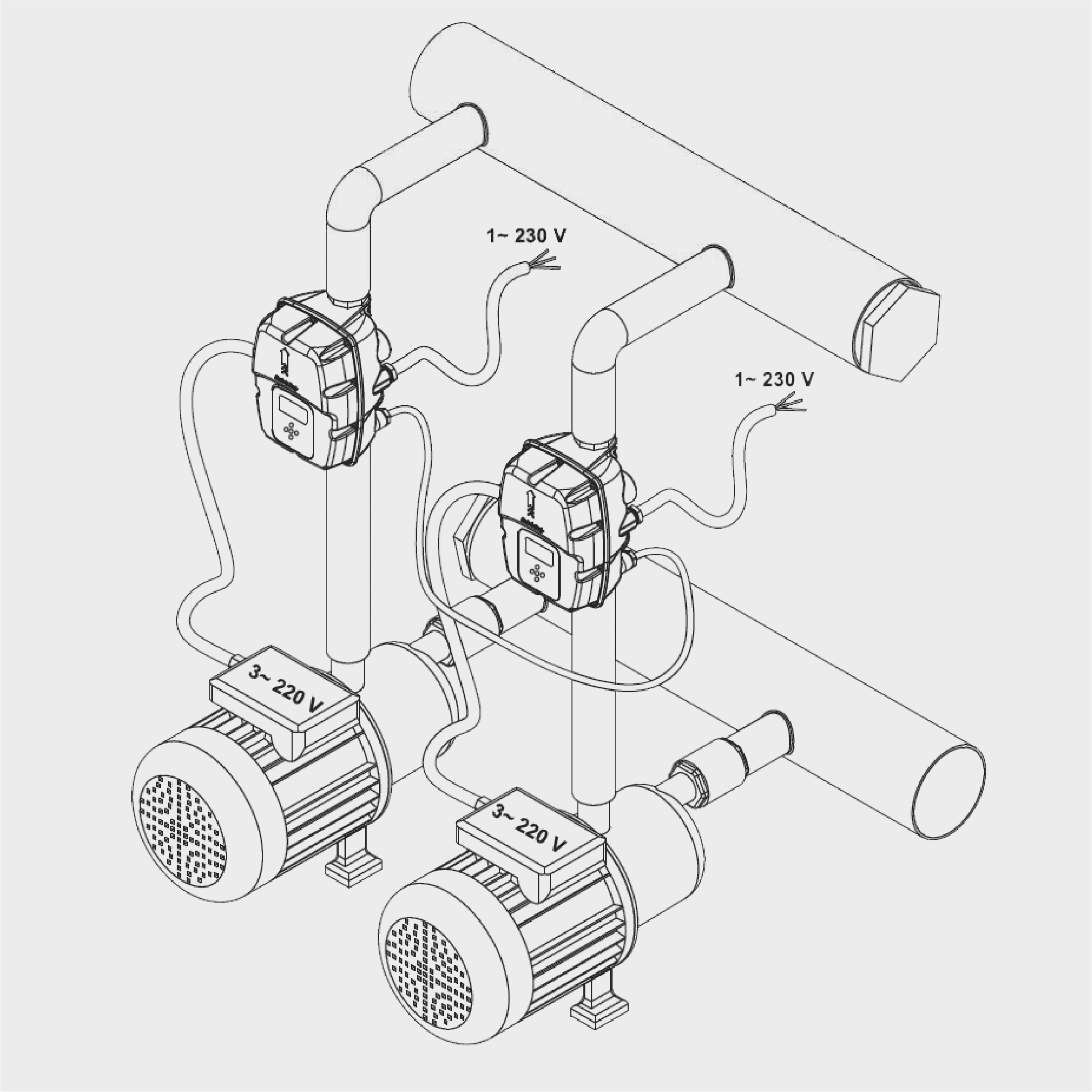

For added flexibility, the inverter features programmable inputs and outputs for different functions, such as enabling double set-points and master/slave configurations. The multilingual display accommodates users from diverse backgrounds, and a Wi-Fi module is available for smartphone connectivity, making control and monitoring more convenient.

Applications:

Electronic Controllers

Inverter with Steady Pressure

Protection Against Dry Running

Specifications

| Feature | Description |

|---|---|

| Control Type | Start and stop functions of traditional electric pumps |

| Pressure Regulation | Constant pressure with integrated pressure transducer |

| Energy Efficiency | Energy saving features |

| Protection Features | Dry running, leakage, overpressure, overheating, rotor blocking, abnormal power supply |

| Digital Display | Pressure, voltage, current, and motor frequency |

| Programmable Functions | Enable, double set-point, error handling, master/slave configuration |

| Wi-Fi Connectivity | Available for smartphone connection |

Additional Information

For optimal performance, ensure that the water used is clean and free from ferrous materials, as the flow sensor can be disabled in such conditions.