Description

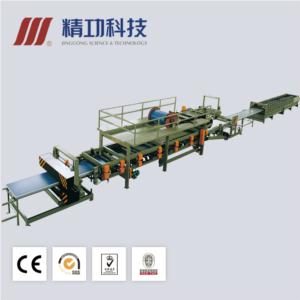

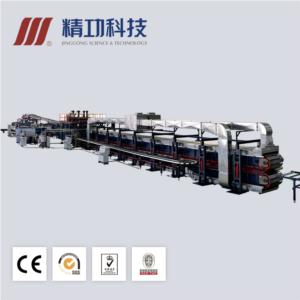

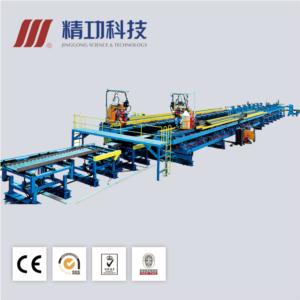

The XBJ series sandwich panel line is a state-of-the-art laminating system designed to efficiently produce corrugated sandwich panels. This innovative line consists of two main components: a roll forming machine and a sandwich panel laminating system. Unlike traditional methods that require manual lamination after sheet formation, the XBJ line streamlines the production process, allowing for direct manufacturing of high-quality corrugated sandwich panels.

Both the roll forming machine and laminating system operate independently, offering flexibility and efficiency in production. The comprehensive system includes a feeding system, roll forming system, and cutting system within the roll forming machine, while the laminating system integrates essential equipment such as decoilers, heating units, and automatic cutting features. With advanced technology, the XBJ series harnesses the synergy of mechanical and electrical components to optimize performance, resulting in an impressive annual output of approximately 500,000 square meters when operated for eight hours daily.

Specifications

| Feature | Description |

|---|---|

| Product Type | Sandwich Panel Production Line |

| Components | Roll Forming Machine, Laminating System |

| Production Capacity | 500,000 square meters per year (8 hours/day) |

| Main Functions | Roll Forming, Lamination, Cutting |

| Independent Operation | Yes |

| Technology Integration | Mechanical and Electrical Equipment |

Additional Information

- Advanced crafting process ensures high-quality panel production.

- Efficient design allows for reduced production times and costs.